To market with new wood and bioplastic 3D printer filament

New Zealand is in a strong position to make 3D printing of biopolymers and composites one of the success stories of our emerging bioeconomy. An abundant variety of renewable feedstocks could be converted into biobased filaments and ultimately renewable high-value products. Imagin Plastics, 3D printer filament manufacturers, are leading by example with their new 3D printer filament that contains a Scion-made wood and bioplastic compound. The filament is 10 per cent by weight New Zealand pine and is 100 per cent biobased and compostable.

The advantages of 3D printing and the strengths of New Zealand’s economy are a combination for success. Geographically isolated, New Zealand relies on importing and exporting goods. A thriving 3D printing industry would enable innovative and localised production that could function within our existing manufacturing network. This new industry could also bring the manufacture of some imports onshore and create new opportunities for manufacturing businesses to export higher value products.

“Being able to work closely with Scion to see a research project over the line and make it to market is an asset to 3D printing in New Zealand.” - Ben Blakley, National Sales and Technical Manager, Imagin Plastics

For Imagin Plastics, the product will serve the growing share of their customers interested in sustainability and biobased plastics, in addition to being a truly kiwi-made product that was designed, developed and manufactured in New Zealand.

Imagin Plastics National Sales and Technical Manager Ben Blakley says, “As FDM (fused deposition modelling) 3D printing grows across all sectors we want to have high-quality options for our clients, and biobased materials is a good one. Being able to work closely with Scion to see a research project over the line and make it to market is an asset to 3D printing in New Zealand.”

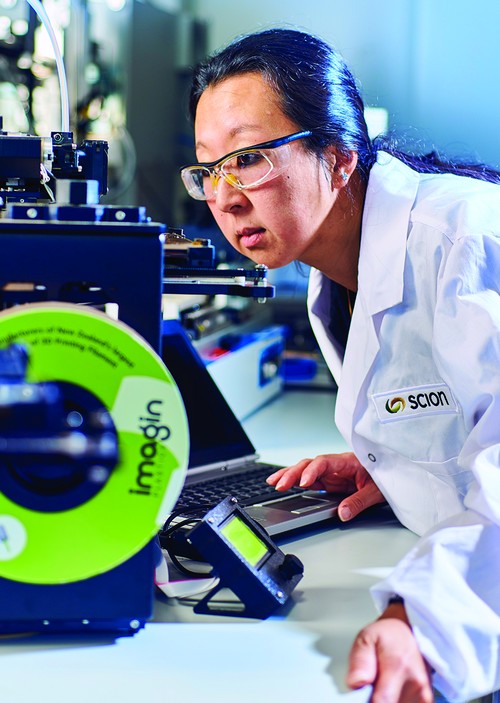

Dr Marie Joo Le Guen, who led the project says, “This product is a great example of research and industry collaboration, and how it could strengthen New Zealand plastic manufacturing industry through innovation”.

The wood within the plastic is a waste stream from the wood milling industry. It is a sustainable resource that would otherwise be discarded or burnt.

A 100 kg supply of the Scion-made compound has been prepared for Imagin Plastics to manufacture the filament, which is now for sale on their website imaginplastics.co.nz.

The product was officially launched on 1 May in Auckland at EMEX 2018. EMEX is New Zealand's largest technology trade show for the manufacturing, engineering, machinery and electronics industries.

Links: https://bit.ly/2Okuo5H