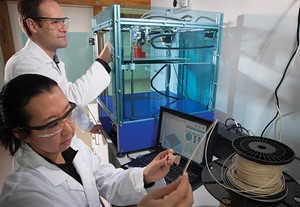

Reconstructing biomass by 3D printing at Scion

An investment in 3D printing technologies enables Scion to develop a range of new bioplastics for use in these technologies, such as filaments (thin strands of material), powders and fibre reinforced filaments.

“As part of the Extrusion PLUS project, we are developing products with advanced functionalities from lignocellulosic biopolymers and bioplastics,” says Dr Florian Graichen science leader for biopolymers and chemicals. “Our challenge now is to work with these biopolymers to formulate bioplastics suitable for use in 3D printing. This would enable a vast range of products from machine componentry to large-scale construction materials to be manufactured from renewable biomaterials with low environmental impacts.

“New ways of processing biomaterials will reduce our reliance on imported raw materials. It will also see more value generated from trees by making better use of lignocellulosic biomass, such as wood processing residues.”

Alongside a role at the head of Portfolio 5 in the recently launched Science for Technological Innovation National Science Challenge, these capabilities have Scion fronting its spearhead project. This will see biopolymers and biofibres from plants and animals formulated by a pan organisational team into advanced biomaterials for 3D printing, targeted at applications of value for New Zealand.

“This project will help overcome key hurdles in using blends of biopolymers and biofibres in manufacturing, and facilitate the design of equipment suitable for processing these materials,” says Florian. “It will fast track the commercialisation of highly functional ‘green’ products using local, renewable materials, which will have an impact on the whole economy.”

For further information

Contact Dr Florian Graichen at Show email