Collaborating to make the world a better place

Around the world

Developing and growing the circular bioeconomy was a common theme running through the international conferences, research collaborations and science exchanges that Scion participated in over the past year. Being active at an international level allows us to contribute to world-leading thinking and research, and to bring the best of new science and technology to New Zealand.

The year saw Scion’s relationships with international partners grow. Formal collaboration agreements and specific joint research projects are in place with many, and a number of partners were included as collaborators in 2017-18 funding proposals.

As part of our ongoing partnership with the VTT Technical Research Centre of Finland, which started in 2016, Executive Vice President Dr Anne-Christine Ritschkoff and Vice President Dr Tiina Nakari-Setälä visited to strengthen cooperation and promote our common vision for the bioeconomy and circular economy. One topic of discussion was our first joint project – adapting VTT’s hemicellulose technology to use different polymers from New Zealand-grown radiata pine to make new packaging products.

Scion’s work with VITO Flemish Institute for Technological Research in Belgium has continued to expand over the last two years. Taking advantage of VITO’s experience in sustainability in the built environment, Scion Sustainable Architect Andrea Stocchero visited VITO at the EnergyVille center in Belgium. In return, VITO Sustainable Built Environment Researcher Sofie de Regel was seconded to Scion for four weeks. During that time, Sofie and Andrea met with stakeholders in the New Zealand building industry value chain. The conversations and insights are being collated to summarise New Zealand’s best practice, barriers and gaps to define how Scion and VITO can support a wider sustainability uptake within the built environment.

Scion and VITO are also delving further into the use of enzymes to produce biopolymers and other high value products from wood residue. With Scion’s strengths in analytical chemistry and polymer characterisation and VITO’s in ester production using commercial enzymes, the two organisations are a good match. VITO Biological Engineer Dr Karolien Vanbroekhoven spent a month at Scion working with industrial biotechnology Research Leader Dr Christophe Collet. While in Rotorua, she worked on defining a new research project building on the research of the first joint sponsored post-doctoral fellow Elias Feghali.

“Our continuing work with VITO on lignin technologies has been particularly satisfying,” said Elspeth. “The success of our joint post-doctoral fellow has prompted VITO to propose investing more and for both parties to fully fund an exchanging postdoc for further work.”

New Zealand and Germany celebrated 40 years of science collaborations in November 2017 at an MBIE-hosted event. Scion was one of six featured organisations. Science Leaders Drs Paul Bennet and Florian Graichen met the German president Frank-Walter Steinmeier and discussed bioenergy and the potential for bark biorefineries.

Bark biorefineries were also the subject of a visit to Fraunhofer IGB in Stuttgart. Florian and Research Leader Dr Warren Grigsby met Fraunhofer staff to progress joint research including scaling-up the technology, raw material logistics and options to widen the scope of the project.

Manufacturing and Bioproducts Science Leader Dr Florian Graichen presented Scion’s packaging work at the Innovation and Sustainability Conference 2017: The Circular Economy for Consumer Goods, in Korea. Florian reported he was able to spend time discussing disruptive thinking and design, biomaterials and sustainable brands, all very relevant topics for Scion.

Florian also attended the Circular Economy sessions at G-STIC – Global Sustainable Technology and Innovation Conference in Brussels. The conference, hosted by VITO and international partners, had a focus on accelerating the development, dissemination and deployment of technological innovations as part of achieving the United Nation’s Sustainable Development Goals (UNSDGs).

Florian reports it was a conference with a difference, with discussions on a policy and political level, rather than about science. “Scion’s research fits on multiple levels including applying circular economy thinking in construction and the built environment, and our clean technology strategies,” said Florian. “Single use plastics were also highlighted as a huge issue.”

“Scion’s research fits on multiple levels including applying circular economy thinking in construction and the built environment, and our clean technology strategies.”

Sustainable wood for a sustainable world was the topic of a global meeting held at the UN’s Food and Agriculture Organisation (FOA) headquarters in Rome. Sustainable Architect Andrea Stocchero presented on and contributed to discussion on how societies benefit from sustainable wood value chains and the challenges that prevent their contribution to sustainable development. All UNSDGs were identified as relevant in some form for forests and forest products.

Andrea was also invited to present at a follow up meeting in Rome, February 2018. Entitled “Halting Deforestation and Increasing Forest Areas”, this initiative was led by the Collaborative Partnership on Forests with other international organisations including the FAO. Andrea presented on how construction and the tree-based value chains address the UNSDGs.

The New Zealand-China Food Protection Network (NZCFPN) has been very active. Technical and Service Leader Lou Sherman is on the leadership team. Lou, with the University of Otago, organised a workshop in China last July with topics that included food contact safety, antimicrobial packaging, sustainable materials and smart packaging. Another workshop was held at Scion in February to help local exporters understand changes to Chinese food contact regulations. Professor Hu from Jinan University was the guest speaker. The next NZCFPN engagement coincides with Scion’s biannual packaging convention in August. Three Chinese experts have been invited to talk on topics including antimicrobial packaging, food contact testing and fibre-based packaging.

Closer to home

Protecting our environment, whether from pests or pollution, describes much of Scion’s collaborative work with other Crown research institutes during 2017-18.

The discovery of myrtle rust prompted a multi-pronged research response, with Scion working with AgResearch, Plant and Food Research, Manaaki Whenua, NIWA and others. A framework for strategic science activities that took into account, short, medium and long term research was developed and the work is underway.

Scion has also been working with AgResearch and Lincoln University’s Agribusiness and Economics Research Unit to work out how much weeds cost the country’s pastoral, arable and forestry sectors. This is thought to be $1.658 billion a year.

How microfibres degrade in water is the subject of new research with AgResearch. Microfibres produced from washing clothes, for example, end up in the sea and marine life. Scion is using its specialist biodegradation unit to compare how wool, a natural protein-based fibre, breaks down in sea water, compared to synthetic fibres such as polyester.

Scion is working with a number of partners on the Healthy Trees, Healthy Future (HTHF) research programme, which is dedicated to combatting kauri dieback and related diseases. These include Manaaki Whenua, Plant and Food Research, Massey University, University of Auckland, Auckland University of Technology, Kauri Dieback Programme, Tangata Whenua Rōpū and local iwi.

Kauri seed collection for 2018 took place in February and March. Pathologists from Manaaki Whenua, kaitiaki from Te Roroa and Kawerau a Maki and others collected cones from healthy trees growing near infected trees in the Waipoua and Waitakere Forests. The cones from 92 trees are now at Scion. Seed from the cones has been sown under strict hygiene protocols in the Scion Nursery kauri polyhouse.

Dr Nari Williams, HTHF Programme Leader, explains: “We are hoping to find natural resistance to kauri dieback in some of these seeds. When they are old enough, our collaborator Manaaki Whenua will infect a selection with the pathogen. Some of the trees from last year’s crop have survived the six-month trials, which is starting to look exciting.”

Scion is also involved in six National Science Challenges: Building Better Homes, Towns and Cities; New Zealand’s Biological Heritage; Our Land and Water; Resilience to Nature’s Challenges; The Deep South and Science for Technological Innovation (SfTI).

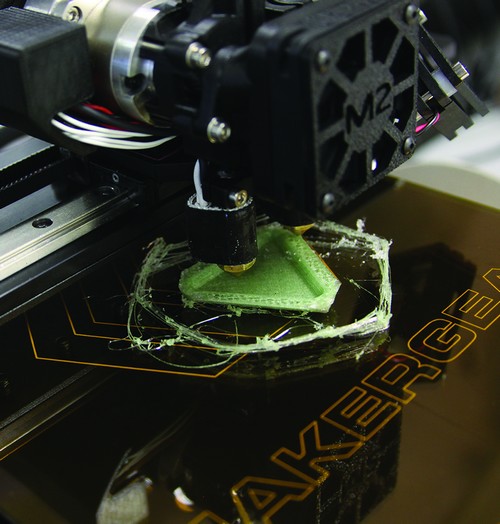

Scion is leading the spearhead project additive manufacturing and 3D and/or 4D printing of bio-composites under the Materials, Manufacturing and Applications portfolio of SfTI. The challenge’s logo is an icosahedron (20-sided solid). Building on the 3D-printed logo presented to the Minister of Science and Innovation last year, a floating version has been developed by ESR.

The four in 4D refers to time. 4D objects and materials can change shape after manufacture. This can be on exposure to stimuli such as heat, humidity or wear. An example could be window shades that automatically open and close, depending on temperature or light intensity.

The annual industry workshop on 3D/4D printing was held at Scion in June 2018. Participants from research institutions and industry were able to see and handle samples and new materials, and discuss where the research might go. For many, it allowed them to think freely and to consider possibilities that they had not thought of before.