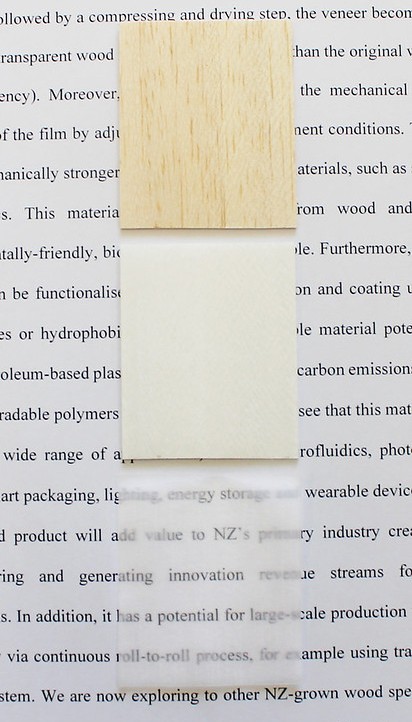

Scientists have created a new wood film that is ultra-strong, flexible and 80 per cent transparent. The wood film is the result of a chemical treatment that removes lignin/hemicellulose from thin layers of wood that are then compressed and dried.

The material becomes 20 times thinner and 25 times stronger than the original wood and mechanically stronger than materials such as steels, alloys and plastics (strength-to-weight). It can be produced sustainably and is easily recyclable and biodegradable.

New functionality can be added to the material’s surface via printing or coating, with functional nanoparticles or hydrophobic molecules, for example. It has already been used in conjunction with a biobased conductive ink to create wood-based flexible circuits that could be used for a wide range of applications, such as sensors, smart packaging and wearable devices.

The potential of this product has already been recognised by industry, receiving a highly commended award in the Wood and Fibre Products Technology and Innovation category in the 2020 Resene Timber Design Awards.

The first step is a chemical treatment that removes lignin and hemicellulose, then compression collapses the cell walls. This process preserves the original alignment of the cellulose nanofibers and encourages their binding. The film is flexible, yet strong in fibre direction.

The first samples were made with balsa wood. The team is now working on exploring the use of New Zealand-grown wood such as pine and eucalyptus, as well as alternative chemical treatments (e.g. wood bleaching and traditional pulping approaches) to make new transparent wood films.

This technology has potential for a scalable fabrication process as well as end-of-life recyclability, making it an ecofriendly alternative to current electronic circuits which create e-waste and use petroleum-based substrates.

Links

Wood-based flexible electronics

Scion’s transparent wood film acclaimed at Timber Design Awards

Funders: Strategic Science Investment Fund

Collaborators: ETH Zurich