The family of sustainable products using Ligate™ adhesive is growing

Commercial trials are proving the value of Ligate adhesive technology in a growing range of engineered wood products.

Engineered wood products like plywood and fibreboard are made from of thin layers or wood particles bound together with adhesives. They are a ubiquitous part of modern homes and offices. The adhesives traditionally used include petrochemicals and the final wood products can emit volatile organic compounds like formaldehyde at levels that may be toxic for people.

Scion scientists decided to address this problem not just by lowering levels of formaldehyde emission but by removing petrochemical components from the adhesives all together. The result was Ligate – a water-soluble, 100% biobased and sustainable adhesive technology.

The chemists and materials technologists who developed Ligate redesigned the adhesive system from the ground up. The inherent properties of each component, including lignin, a by-product of pulp and paper manufacture, were considered, as well as how the components might interact with each other and be utilised together.

At the same time, the final adhesive had to be able to be made in existing manufacturing facilities and be able to be “dropped-in” to established wood panel processing operations. This “value chain” approach has allowed for fast scale-up and easier access to commercial plants to refine the Ligate formulations and produce trial material for further applications and product developments.

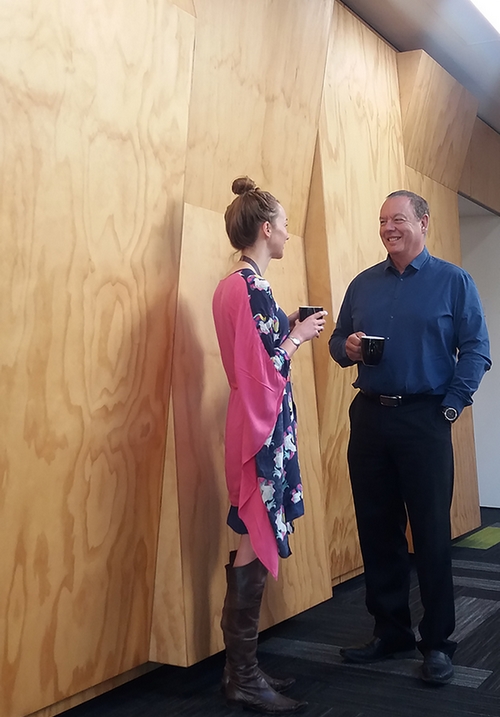

The odd “sticky” situation has been encountered. Four tonnes of Ligate were successfully manufactured in September 2018 for producing plywood with these panels incorporated as a feature in recent renovations at Scion’s Rotorua campus. More than 20 tonnes of high density fibreboard for interior use have been made (March 2018) leading to product launches planned for later in 2019.

The evidence for the benefits of Ligate comes from extensive science from collaboration with international researchers showing that formaldehyde emissions from Ligate-containing products are lower than the emissions from natural wood. Also, comparisons of the life cycle impacts of medium density fibreboard (MDF) made with Ligate and standard MDF resins show reduced impacts on human health and resource depletion.

This year, Ligate technology is a finalist in the New Zealand Plastics Industry Design Awards, Research and New Innovation Award. It was also NZBIO’s (now BIOTechNZ) 2016 Biotechnology of the Year.

Ligate adhesive technology is meeting worldwide demands from manufacturers and consumers seeking more sustainable products that contribute to healthy home and work spaces. Made from trees sustainably grown in New Zealand, Ligate-containing products also sequester and store carbon, helping to mitigate climate change. Ligate is shaping up nicely to be an essential technology for the environment and the growing bioeconomy.