Over 2 million tonnes of bark are produced by New Zealand’s forestry industry every year. It is an underutilised resource, which could be worth $400 – 600 million annually if put to use.

Pine bark is a rich source of polyphenols, terpenes and resin acids that have unique functional and structural properties including antioxidant, antibacterial and waterproofing properties.

New technologies and integrated processing are needed to recover all the potential value from bark. Scion is setting out to create new processes and products through our highly collaborative Bark Biorefinery programme.

Industry involvement is key to building a successful value chain around a New Zealand bark biorefinery. Over 20 organisations from across New Zealand came to the table at the Bark Biorefinery Industry Workshop in November 2019. Their participation helped initiate an industry engagement strategy for the programme.

Mark Glenny, Innovation Research Manager from Resene, attended the industry workshop. He says, “Sustainability is important to Resene, and one way we can make a big impact is to source more sustainable and renewable raw materials. The bark biorefinery project gives us the opportunity to do this, and we’re excited about the potential product streams the project could create. The industry workshop gave us the chance to discuss the various approaches to achieving this alongside a wide range of other businesses.”

Great progress has been made in extracting, analysing and quantifying bark components, together with matching new applications for products from bark.

A commercial-scale, supercritical fluid extraction of bark resulted in range of products and materials. One of the extracted materials is a mixture of soft, natural waxes much like petroleum-derived paraffin wax. These natural waxes could be used as waterproof or water repellent surface coatings, and in cosmetics and skin care as emollients, for example.

The extraction of tannins to treat leather is another avenue being explored. Although tannins have been used in the leather tanning process for centuries, most processes today use chromium, which is toxic both to humans and the environment. This part of the project team has been working with New Zealand-based partners to identify and develop the right bark tannin fraction for leather tanning, opening possibilities for producing environmentally friendly, luxury New Zealand leathers.

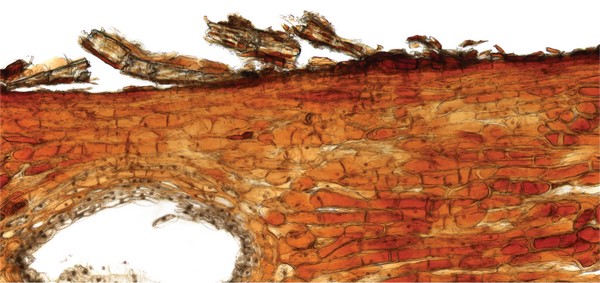

Suberin is a water-repelling polymer found in the cell wall of bark. Extracting suberin materials has been the focus of a collaborative effort from the Scion team, ITQB/University of Lisbon and University of Auckland. These bark-derived water-repelling polymers could be a sustainable alternative for petroleum-based materials used in many products such as paper coffee cups, rainwear or touchscreen coating technology.

The project team has also been working on alternate ways to extract and process bark, in conjunction with German research and development organisation Fraunhofer. This will complement the supercritical processing technology that is also being explored.

Moving up the supply chain, the team has also carried out a comprehensive study of bark components based on tree height. This understanding will be key for directing the processing and flows of differing barks within an operational bark biorefinery.

Finnish research institute, VTT, has also been involved, assisting with an initial techno-economic assessment for the first-generation bark biorefinery with extract and solid energy products.

The ‘bark biorefinery’ is just one piece of our transition to a circular bioeconomy. With this advanced technology and science, we can create solutions for problems such as our reliance on fossil fuel-based products. Biorefineries, and specifically bark biorefineries, will form an important part of this strategy and become a critical step in our move towards a circular bioeconomy while meeting many of the government’s goals for an environmentally and economically sustainable future New Zealand.

The bark biorefinery project runs from 2018-2023.

Funders: Ministry of Business, Innovation and Employment

Collaborators: VTT (Finland), Fraunhofer IGB (Germany), ITQB NOVA University of Lisbon (Portugal) and University of Auckland