Paper-based filter plates embedded with molecular imprinted polymers (MIPs) are cleaning up thanks to a collaboration between Scion and Ligar.

MIPs are polymers with impressions designed to capture and remove specific target compounds. This ability to selectively capture and filter material at molecular scale is critical for concentrating, refining and purifying processes. Many industries make use of such highly specialised functionality. For example, MIPs can be used to recover valuable metals, or extracting unwanted flavour-producing compounds from food and beverage products, such as wine.

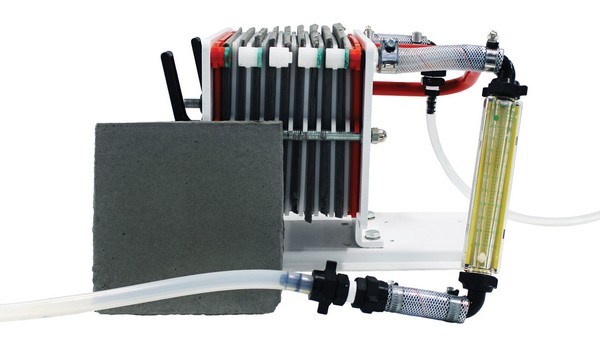

MIPs are usually deployed in powder form and are mixed with the purified material to complete the desired recovery and extraction before being filtered out. Ligar, a Hamilton-based company specialising in molecular extraction technology, has been working with Scion’s material and pulp and paper experts for two years to develop a paper-based filter plate incorporating MIPS that combines the removal and filtration steps into one efficient process.

Several technical challenges had to be addressed during the development of the new filter systems allowing them to work highly selectively and efficiently. The filters are also suitable for food contact applications. A joint patent application has been filed by Ligar and Scion.

The paper plates have been developed as a replacement for commercially available systems. This has made the technology transfer and the uptake of the new products easy and users are able to swap existing commercial plates for the highly specific paper filters.

Due to ease of slotting in the market space and targeting a real demand, the filter plates have raised a lot of commercial interest in a range of industries, from food and beverage to environmental cleanup. Several trials have been completed targeting a broad range of compounds. Ligar works directly with businesses to provide customised filter and separation solutions.

This project was a success due to the close collaboration between Ligar and Scion during all development stages.

Scion anticipates that MIPs and filters could play a big role in biorefining, addressing one of the biggest challenges of biorefining - separation and purification of the products. MIP technology may be the key to success here.

“Our product development team was looking for a novel way of using imprinted polymers within filtration systems and one of the options was to incorporate them into filter plates. Bringing their expertise in papermaking and fibres, the Scion team worked closely with ours to develop novel and scalable methods to make the plates, with the critical factors being even dispersion of polymer within a structurally sound material, the use of food-safe ingredients and the avoidance of any impact on flavour. The collaboration worked very well, beginning with making papers that could be tested for performance before moving onto plates. Our team appreciated the knowledge and capabilities of the Scion team, along with the flexibility to adapt to challenges throughout the process.” - Nigel Slaughter, Chief Exploration Officer, Ligar

Funder: Strategic Science Investment Fund

Collaborator: Ligar