Fund is catalyst for international collaborations

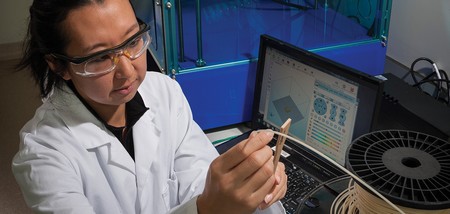

Dr Marie Joo Le Guen examining bio-based filament for 3D printing.

An exploratory visit to Europe last year by scientists in our Manufacturing and Bioproducts Group is already paying dividends for at least two scientists.

“The development of 3D printing has allowed us to produce objects that have never before been possible with traditional manufacturing techniques, creating new market opportunities,” says Marie Joo. “This funding will enable us to develop a 3D printing method that uses bio-based materials, particularly by-products from primary industries that are cheap and readily available.”

Natural resources are not consistent, Marie Joo explains, and Scion has already demonstrated that bio-based materials require specific handling and modification to be suited for 3D printing.

“Our work with AUT has highlighted some of the processing shortfalls. The printing equipment needs to tolerate the irregularity of the feedstocks.

“Our focus will be on using materials sourced from primary industry waste.

We are particularly interested in sea shells that currently have no resale value and in some cases, incur disposal costs.”

Marie Joo’s expertise in biopolymers means she will concentrate on developing and testing suitable biomaterials for 3D printing. Based on their engineering and micro-tooling skills, scientists from Chemnitz University of Technology and AUT will modify 3D printers to suit bioresource use, which will be evaluated through complementary experiments. As Marie Joo says, “the partnership is built on existing synergies in 3D printing, with different but complementary expertise.”

Stefan Hill will be using his $150,000 to develop an additional method of authenticating bio-plastics. At present, the only method of doing this is by using radioactive carbon (C-14) dating.

“Bio-based feedstocks provide a clean and sustainable source of polymers. However bio-plastics are, on average, more expensive to produce and therefore command higher premiums. Customers need to be confident they’re getting what they pay for,” says Stefan.

“Fossil-based materials do not contain C-14, whereas corn, for example, absorbs C-14 from the atmosphere. However, fossil-derived carbon dioxide can sometimes be used to enhance plant growth and this results in a bio-based plastic being reported as fossil-based instead. It’s also easy to counterfeit a bio-based claim by doping fossil-based polymers with young carbon.”

Stefan will be working with GNS and the Energy Research Centre of the Netherlands to investigate tritium-dating as an additional method of evaluating bio-based products. Tritium is a radioactive isotope of hydrogen and much more difficult to counterfeit. Having two methods of validation will add more certainly around the ultimate source of plastic and make it difficult for counterfeit products to enter the market.

“This is an opportunity to develop an enduring partnership with two other centres of excellence,” says Stefan. “The Energy Research Centre of the Netherlands also helps set international standards for bio-products and this programme will elevate our existing relationship with them as an advisory partner on an EU programme to the next level as an active non-EU research partner.”

For further information

Contact Dr Marie Joo Le Guen at Show email

Dr Stefan Hill at Show email