Green sensors a step closer to reality

Real time information about the conditions being experienced by New Zealand export products may soon be provided by biobased sensors being developed by Scion.

The majority of New Zealand’s primary produce is shipped internationally. To ensure goods like kiwifruit, apples and meat arrive in the best possible condition, they need to be stored and shipped at appropriate temperatures and humidity and not subject to physical shocks, for example.

In an ideal situation, it would be possible to monitor the whole supply chain and provide real time data to remote users to alert them of significant events in time to prevent potential product loss. Current sensor systems, however, have trouble meeting these requirements. They may be big and bulky, require a lot of energy, data may not be able to be transmitted long distances, or only be accessible at the end of a journey and often do not meet green credentials.

Prototype biosensors

An essential first step in developing biobased sensors has been showing that we can overcome these issues by using commercially available, metal-based technology. A prototype that uses a combination of GPS, cellular technologies and a short-range mesh network that can be installed on pallets has demonstrated this is possible.

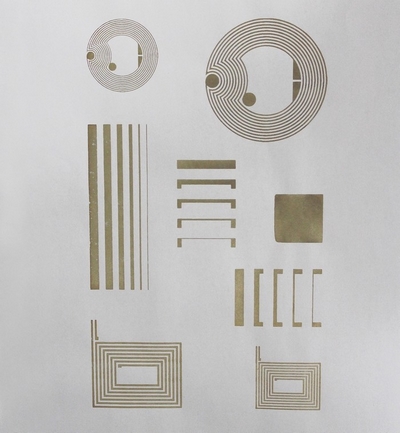

Scion technologists and engineers are now exploring the possibilities for replacing components of the monitoring system with biobased alternatives. The potential for these has been demonstrated by the development of a fully biobased, flexible, strain sensor.

The prototype sensor uses a conductive ink containing lignin carbon fibres combined with a biobased binder and is printed onto a flexible wood film. Biobased, wood-derived flexible electronic devices have potential for use in a wide range of applications.

Circular, biobased solutions

The use of biobased products that can decompose at end of life to replace sensors currently made from a variety of metals and plastics is a great example of circular bioeconomy thinking. Swapping non-renewable resources with renewable replacements will lead to reduced environmental footprints and help minimise waste.

Better monitoring of goods as they move through the supply chain will also provide a full picture of the demands on packaging used to ensure the goods reach their markets in sound condition. This data will help packaging technologists develop materials and design new, lighter, stronger packaging that better protects the goods within.

International produce shipping is big business. The combination of better sensors, biobased materials and improved packaging will reduce spoilage and waste and ensure that the primary products that are essential to New Zealand’s post COVID-19 recovery reach our global markets in the best possible condition.

Scion has been working with Plant and Food Research Limited (PFR) and Massey University on this project. PFR has carried out trials to compare the advantages and disadvantages of different existing sensor technologies. Engineers from Massey University’s Department of Mechanical and Electrical Engineering have assisted in the development of the prototype’s remote, real time monitoring system.