Creating a future from trees

The beauty of wood

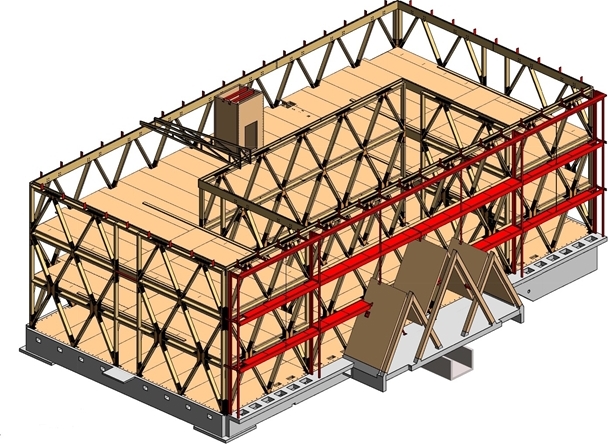

The essence of Scion’s building speaks very honestly about our intent. We are a Crown Research Institute for forest and wood products, and a timber diagrid structure is our home, located amongst tangata whenua’s Tokorangi forest.

Triangular shapes used in the design reflect those found in our natural environment. There are 88 diamond and triangle-shaped frames made up of 4,248 parts of laminated veneer lumber (LVL).

The diagrids provide the required stiffness and strength while using less material than would typically be used in a building of this size.

The diagrid LVL is fixed with timber dovetail node joints that transfer the loads, and steel connectors that will deform in an earthquake.

Testing found that, after an earthquake, the test building’s pre-earthquake strength would be restored by simply replacing the steel connectors that had absorbed the earthquake energy and deformed, while the engineered timber elements remained intact.

Te Whare Nui o Tuteata gets the best performance from steel and timber.

The building is a scientific demonstration of what is possible with construction using wood – beautiful, innovative and embodied-carbon neutral.

Future timber buildings will be taller and more carbon efficient thanks, in part, to Te Whare Nui o Tuteata and the team of team of engineers, designers and builders who weren’t afraid of a challenge.

Commitment between Scion and local hapū

As well as addressing strength, resilience and attention to the environment, the building recognises the commitment between Scion and tangata whenua. This culminated in Ngā Hapū e Toru gifting the prestigious name Te Whare Nui o Tuteata, which acknowledges the mana of the tupuna (ancestor) Tuteata, with the connection to the whenua (land) where the building sits.

The three computer numerical controlled (CNC) engraved glulam peaks at the building entrance represent the three local hapū Ngāti Hurungaterangi, Ngāti Taeotu and Ngāti Te Kahu. The kōwhaiwhai designs were also gifted from their wharenui (meeting house) Hurunga Te Rangi.

The custom-designed wooden ceiling features ceiling lights arranged to represent the Matariki star cluster.

A wrap around coloured curtain wall clads the building in colours that reflect the forest canopy and acknowledge the cultural significance of the land. Traditional tukutuku weaving inspired the double-skin façade with coloured glass filtering the sun, while internally creating the effect of dappled light falling onto the floor below.

Award-winning architecture

The building was designed by RTA Studio in collaboration with Irving Smith Architects. It has pushed boundaries for what can be achieved with innovative design and timber construction, winning a raft of both local and international architecture awards along the way.

To date, it has won 14 awards, including two World Architecture Festival awards (World Best use of Certified Timber Prize; World Higher Education and Research), and a New Zealand Institute of Architects National Award (NZIA) (Commercial). The building and designers were also honoured with the prestigious Purple Pin at the Designer Institute of NZ’s Best Awards for 2021.

Valuing matauranga Māori

Forests and trees are culturally significant to Māori. They are central to the distinct worldview that is Te Ao Māori. Māori are a key resource holder and are intergenerational.

New Zealand’s forests also are economically and socially important for Māori. Through forestry, Māori contribute hugely to New Zealand’s economy. Since 1997 more than 70 state-owned forests have been returned to iwi in Crown Treaty settlements. Māori ownership of land and forests will increase as settlements conclude.

At Scion, we have embedded Māori partnerships throughout our organisation. We now have a dedicated Māori Research and Partnerships Team that is leading and supporting Māori research in partnership with Māori.

It’s an approach that’s leading to very authentic, world-leading and exciting programmes of work, where we are seeing genuinely Māori-led research, and respect for matauranga Māori.

We see an exciting future with our partnership with tangata whenua, Ngā Hapū e Toru, who will work alongside us to unlock ground-breaking research opportunities.

Circular bioeconomy provides direction

Our forests are a massive renewable resource with the scale needed to provide New Zealand with low-emissions materials and fuels to help meet our climate change commitments.

Anything made from fossil-based materials today can be made from a tree tomorrow.

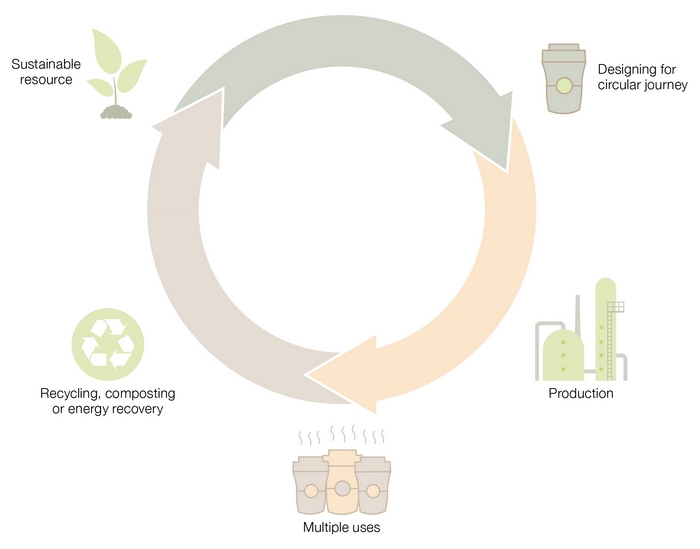

A circular economy is centered around people and nature – getting the most value out of renewable biological resources while minimising waste.

The essential concept at the heart of the circular bioeconomy is to ensure we can unmake everything we make in a clean, non-polluting and regenerative way. For designers and product developers, that creates new opportunities. Instead of take, make, waste we now need to think about how the product will be used and what its whole ‘life’ will be – waste is a concept not found in nature.

Scion can help New Zealand make the transition to a circular bioeconomy through research that explores low-carbon alternatives to materials and energy made from fossil fuels.

Mitigating climate change is the challenge of our generation. Creating prosperity from the transformation to a circular bioeconomy is an opportunity that we must embrace for the benefit of future generations.

Exploring new opportunities

The circular bioeconomy is estimated to be a $30 billion per year opportunity for New Zealand.

We will help transition to a circular bioeconomy through research and key partnerships.

Scion scientists are already finding new ways to grow resilient forests that are planted and managed not only for their production value, but also create jobs and improve our natural environment. Both indigenous forests and exotic species play a role in New Zealand’s future forests.

We’re protecting and nurturing the forests that you love

Our scientists are improving propagation techniques and technologies to accelerate the commercial scale production of high-quality indigenous trees.

We’re finding cutting-edge ways to manage and monitor forests

Drones are already changing the way we manage and monitor forests. Sophisticated cameras in the skies (or space!) allow us to detect diseases, weeds, water stress or nutrient imbalances on individual trees.

We have drones in the skies that are powerful enough, and clever enough, to drop a precise amount of fertiliser to a pine seedling or zap weeds with herbicide. Using soil maps, slope, aspect, weather reports and tree size, we will soon be able to precisely manage a tree differently from its neighbours. All this is done remotely, safely and over difficult terrain. The forester of the future will spend less time slashing through blackberry and more time managing and creating insights from terabytes of data.

We’re developing tomorrow’s products from today’s trees to contribute to a bio-based future

Forests will grow a new bioeconomy from which new materials, bioproducts and biofuels will make a difference to our wellbeing and environment.

Packaging for the future

Packaging is one of the key enablers for any nation undergoing the transition from a linear to circular economy. We need to move towards more easily recycled packaging, fewer multi-material packages and a dramatic reduction in single-use plastic packaging. Use of biobased polymers to replace petrochemicals, will be part of the solution.

Equally, it is important for New Zealand manufacturers to meet the increasingly high environmental standards for packaging that are demanded by overseas markets, while also protecting products.

As such, the need for fibre-based packaging is increasing rapidly. We are well placed to support this growing demand through research at Scion.

Plastics manufacture and processing

Scion has specialised equipment and capability to deliver innovative plastics that supports a circular bioeconomy through biopolymers, additives, wood plastic composites, and their derived products, for industry. Many of the plastic and bioplastic materials we develop are renewable and/or compostable and are often derived from biomass feedstocks.

Equipment includes our laboratory-scale thermoformer, which our scientists use in plastics thermoforming applications, including packaging using bioplastics that incorporate a range of fibre-based residues, such as wood and hemp.

Commercialising seaweed hydrogels

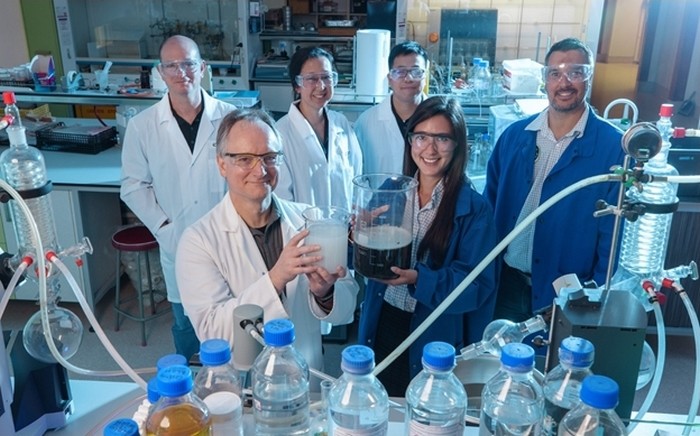

Scion scientists have partnered with AgriSea to develop nanocellulose from the company’s seaweed waste stream to help create a high-value and sustainable aquaculture industry in Aotearoa.

The award-winning collaborative work has drawn on Scion’s wood pulping experience. Our scientists have found a way to extract nanocellulose from seaweed, which is then used to make hydrogels (polymers that can absorb up to 100 times their own weight in water).

Seaweed nanocellulose is a renewable replacement for fossil fuel-based polymers in hydrogel products, and has many high-value applications, including batteries, adhesives, biomedical supplies and cosmetics.

A successful scale-up trial has provided enough material for further product development. In August 2022, the Government announced it was loaning AgriSea $750,000 from the Regional Strategic Partnership Fund so it can expand its operation and establish a $1.5 million commercial seaweed-based nanocellulose manufacturing plant at its site in Paeroa – a world first.