Transforming the properties of lignin in softwoods

12 May 2015

12 May 2015

Radiata pine that is easier to process into pulp and biofuel is one step closer thanks to a team of Scion biotechnologists working in collaboration with the University of Wisconsin-Madison.

Easier-to-process softwood brings economic and environmental benefits. Needing less energy, the pre-treatment processes will be faster, more efficient and less wasteful, yielding improved feedstock for the pulp, paper and biofuel industries.

Led by Dr Armin Wagner at Scion, the team has just published its work proving that it is possible to change the makeup of lignin polymers in softwoods in the Proceedings of the National Academy of Sciences.

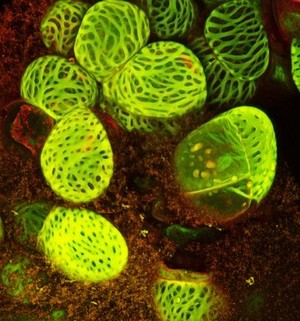

Dr Wagner, explains: “Lignin is a complex polymer that provides strength and structure in trees. In softwoods, like conifers, the lignin contains guaiacyl (G) units while hardwood lignin also contains syringyl (S) units. Lignin made up of G units is more condensed and difficult to degrade than lignin that also contains S units. This, together with the higher levels of lignin found in softwoods, makes trees like radiata pine more complicated and expensive to process than hardwoods.

“We have shown it is possible to engineer cells of Pinus radiata to produce S lignin units. This suggests it is possible to engineer softwoods, such as radiata pine, to produce easier to process hardwood-like lignin while retaining their outstanding fibre properties.”

Metabolic engineering allows plant breeders to introduce a single, clearly identified desirable trait into a population where it is not normally or readily available. The materials used in this work were obtained from naturally occurring organisms such as bacteria, fungi, and plants.

The paper is available at http://www.pnas.org/content/early/2015/04/16/1411926112.full.pdf. The corresponding author is John Ralph, University of Wisconsin-Madison professor of biochemistry and plants leader at the Great Lakes Bioenergy Research Center.

ENDS