Compostability testing services

Being able to design, manufacture, test and certify compostable products and materials is crucial for the success and future growth of New Zealand’s packaging and plastics related businesses.

Scion can measure the compostability of a range of different materials under varying conditions including industrial composting and home composting.

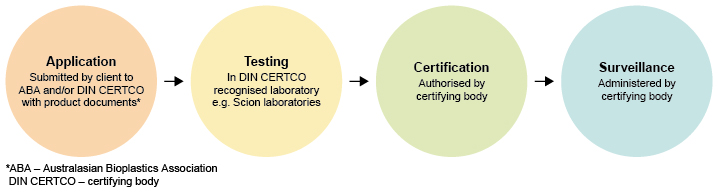

Testing is undertaken in accordance with internationally recognised standards and Scion is the only DIN-CERTCO-accredited testing facility in Australasia. DIN-CERTCO confirms that our compostability testing is meeting specified requirements including those for quality, safety, efficiency and reliability. Please note that Scion is NOT a certifying body; the results of our testing can be used in support of certification. To apply for certification, you will need to directly contact an appropriate certifying body (DIN CERTCO or the Australasian Bioplastics Association - ABA), before testing can commence.

To be certified as compostable, materials have to pass a range of different tests:

- chemical characterisation

- biodegradation

- disintegration

- ecotoxicity of generated compost.

“This kind of information will help consumers make informed choices about the products they buy.” - Kate Parker

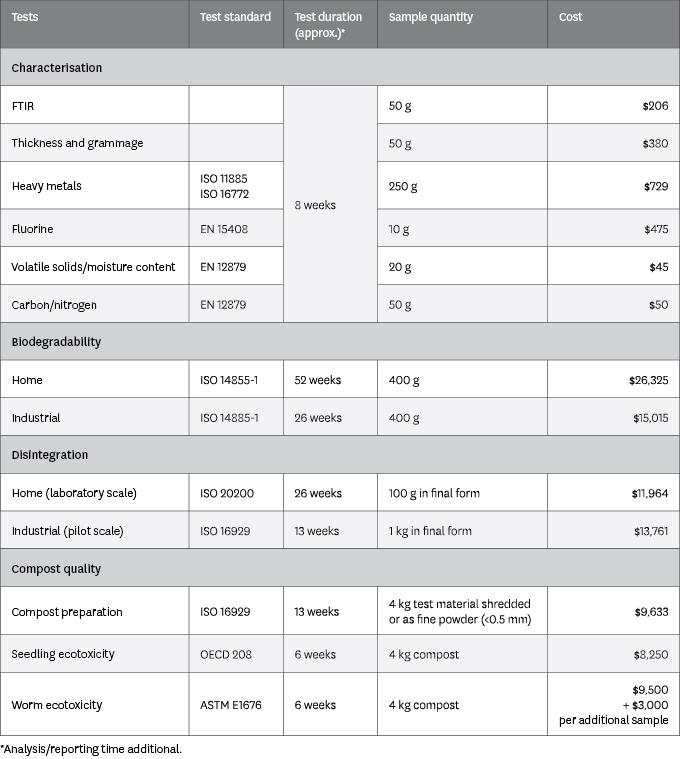

Standard tests and indicative costs

Biodegradation facility

Scion houses the only accredited biodegradation facility in the southern hemisphere. Our dedicated team of scientists test the transformation of a product from its original starting material to carbon dioxide and water. The Scion biodegradation laboratory is committed to testing various materials under simulated, home and industrial conditions for either research and development, or certification purposes. Scion’s thorough testing and expert insights have guided the development of many different certified global eco-friendly, products – thus aiding industries in reducing their environmental footprints.

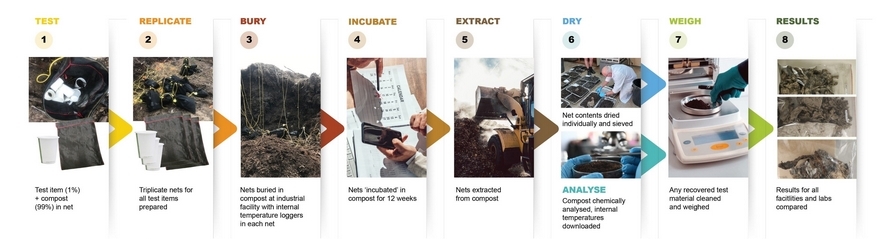

Disintegration facility

Scion’s new disintegration facility provides information on how materials degrade within an industrial composting environment. Staffed by an accomplished team of scientists and technicians, Scion can provide disintegration testing for certifying or research and development purposes using the forefront of innovative technology and meticulous experimental design. Our goal is to offer knowledge into how a material will disintegrate under real world industrial composting conditions.

Case Study: The Waste Minimisation Fund Compostability Field Trial

Much single-use compostable food packaging in New Zealand ends up in landfills rather than being composted. One reason for this is consumer confusion around how products identified as compostable can be treated at end-of-life. In addition, there are concerns about the extent to which these materials degrade in the range of composting environments used throughout the country. A practical study led by Scion investigated how materials branded as compostable disintegrated in real world settings in a New Zealand context.

FAQ

How long does testing take?

Testing depends on the type of test and product itself. Material characterisation can take up to 8 weeks while home biodegradation can take anywhere up to a year. Please refer to our costing and timeframe table for rough timeframes.

Where are Scion’s biodegradation and disintegration labs located?

Both the biodegradation and disintegration laboratories are located at Scion’s headquarters in Rotorua, New Zealand.

Is the Scion laboratory accredited?

Yes, we are. Scion is recognised by DINCERTCO and in-line with ISO 17025. The accreditation covers all testing standards involving biodegradation and disintegration.

Can Scion help me develop products?

Scion’s services for compostability are restricted to laboratory testing only – we do not take part in product development. However, our dedicated packaging team can offer valuable insights into not only compostability, but also other end of life product solutions such as recyclability. Our team will share how we think your product will perform or degrade in certain environments, and what you need to consider to obtain desired characteristics for your products.

Scion provides a range of other services, please see our services section for more info.

Why is 90% biodegradation sufficient for certification? Does this mean there are 10% microplastics left?

A 90% biodegradation result is actually a 90% carbon to carbon dioxide (or methane) conversion, with the remaining 10% the biomass yield. It is effectively 100% or complete biodegradation as all carbon in the product has been converted.

When a product undergoes aerobic biodegradation, there are two routes for the carbon:

- to carbon dioxide production, which we track during the biodegradation process.

- to new microbial biomass, which cannot be tracked and is defined as the biomass yield.

Where can I go with Scion reports?

As Scion is DIN CERTCO accredited, which is a globally recognised certification body, you can approach DIN CERTCO and ask to use their labels on your product. Alternatively, you could use the reports for research purposes, marketing, or legal claims, depending on the test conditions and the level of quality control.

Does Scion offer certification?

We are an independent testing laboratory which means we cannot offer certification. We can assist you in obtaining globally recognised DIN CERTCO certification.

How does Scion track biodegradation?

We use a sensitive carbon dioxide monitoring system to precisely track the production of carbon dioxide (biodegradation) over the course of the test. From this we can calculate the rate of biodegradation over time. Measuring evolved carbon dioxide is the only parameter to correctly track biodegradation over time.

What is biobased?

Biobased carbon content is the amount of carbon in a product which comes from renewable (non-fossil based) sources. A product that is biobased is not necessarily biodegradable and vice versa.

What is the difference between biodegradability and compostability?

Compostability is a broader term than biodegradation, all compostable products biodegrade but not all biodegradable products are compostable. The key factor is that compostable products do not have any toxic element to the environment after degradation. A product that is biodegradable under composting conditions is not necessarily compostable, as the material characteristics, timely disintegration, and ecotoxicity must also be verified for full proof of compostability.

What is disintegration?

Disintegration is the physical degradation of a product, how it fragments and breaks down into smaller pieces. Even though disintegration can be caused by microorganisms, this is not proof of (complete) biodegradation since the sample may just be fragmented into invisible micro-particles.

Why is biodegradation tested in different environments?

Every environment is different with its own microorganisms, temperature, and other inherent characteristics. Biodegradation of products changes from one environment to another - a product may biodegrade rapidly in one environment but could go very slowly, or not degrade at all in another. Reliable, independent test data in these different environments is therefore important. The environment chosen depends on the typical end-of-life destination of the material to be tested.

What is biodegradation?

Biodegradation can be either aerobic or anaerobic. Aerobic biodegradation is the biochemical conversion, through the activity of microorganisms, of organic carbon into carbon dioxide and water. Anaerobic biodegradation converts organic carbon into methane and carbon dioxide.

What is compostability?

Compostability is the breakdown of a material into organic matter, through the action of microorganisms, such as bacteria and fungi. This includes both biodegradation, which is the breakdown on a biochemical level, and disintegration, which is the timely breakdown on a physical, visual level. Besides degradation, compostability also guarantees environmental safety. Consequently, testing for compostability encompasses four major aspects: material characteristics, biodegradation, disintegration, and ecotoxicity.