Biodegradable vine clips go global

Solving the problem of microplastic pollution in vineyards has led to even more eco-friendly products for one company.

A successful research partnership with Scion is bearing fruit for a Christchurch company exporting biodegradable vine clips and filling demand from global winegrowers for more sustainable practices on their vineyards.

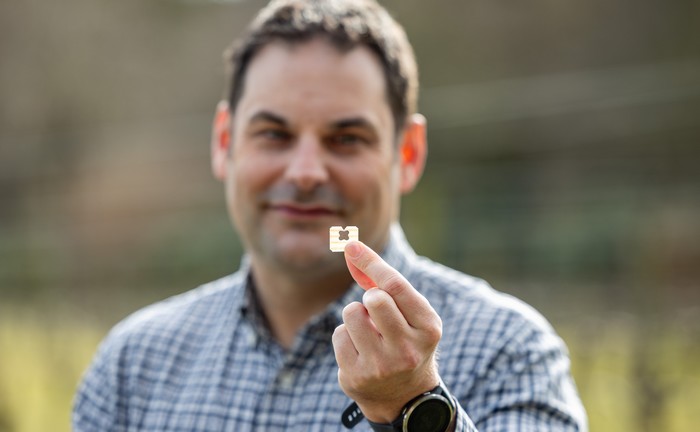

Starting this year, PolyNatural® has taken commercial orders for its eco-friendly vine clips from vineyards across South Australia and New Zealand. Made from biodegradable polymers and waste materials sourced from wood processing, the vine clips are designed to replace traditional plastic clips that are used to hold nets over ripening grapes to keep birds and other pests away. About 30 million of these plastic clips are used by the New Zealand wine industry every year.

Reaching the export milestone follows extensive product development and trials on vineyards in New Zealand and comes five years after the first prototype clip was created by Scion scientists in collaboration with PolyNatural®’s parent company EPL.

PolyNatural® general manager for Sales and Marketing, Gareth Innes, says the commercialisation process has been a journey of discovery.

“Good things take time and we’ve spent several years collaborating with Scion by testing formulations, using different materials and doing a lot of field research to develop a product that we’re confident winegrowers are very satisfied with.

“Scion’s research support and the feedback we received during trials has helped us to create a world-class product that is helping the global wine industry combat a major environmental issue.”

Scion’s research support and the feedback we received during trials has helped us to create a world-class product. - Gareth Innes

Stamping out plastic waste

Vine clips and netting are essential to wine growing operations for pest management and to prevent fruit loss. But after six to eight weeks, nets are removed, and clips fall to the ground. This leaves a growing pile of non-degrading plastic littering vineyards that, over time, contributes to microplastic pollution.

With the viticulture industry keen to adopt more sustainable practices and stamp out plastic waste, Scion began developing a faster-degrading vine clip made of grape marc and bioplastic. Led by researchers Dawn Smith and Stephanie Weal, Scion trialled different prototypes in the field, testing numerous formulations before arriving at the right mechanical and physical properties.

In 2020, EPL took up the challenge of improving the clip even further and getting it ready for production at scale. “The technology and materials that we’re using now are different to what they were five years ago, but we couldn’t have achieved what we have if it wasn’t for the work that Scion did in those early trial stages,” Innes says.

In 2020 EPL and Scion were recognised at the Sustainable Business Awards by winning the award for Outstanding Collaboration for the work on the predecessor to the PolyNatural® vine clip.

The vine clips are 100% biobased using renewable materials that have no petrochemicals or toxic additives and comes from waste generated from processing wood. That waste is then fermented using micro-organisms and shaped to create a durable clip that can fully degrade in the right soil conditions.

Everyone knows that they can’t recycle their way out of the environmental plastic problem. - Gareth Innes

Opportunities ahead

Lessons learned during the commercialisation process and further market research has sparked additional biodegradable products for the horticulture, viticulture and marine industries.

To support demand for riparian planting and land revegetation projects, PolyNatural® began trialling biodegradable plant protectors in 2021 to improve the survival rates of young plants from pests and the elements. The product range was launched commercially earlier this year.

PolyNatural® is also working on eco-friendly ties for the kiwifruit industry. “There’s huge market demand for our prototype as we estimate the industry uses about 100 million plastic ties every year to hold their vines down,” Innes says. Currently, most vine ties end up on the ground.

New Zealand’s fishing and aquaculture industries are also set to benefit from PolyNatural®’s technology and business growth. It is part of a collaboration that is working to solve the problem of plastic waste at sea caused by abandoned or lost fishing gear. Early testing is underway of a new biobased material that could be used in a range of durable products designed to fully biodegrade in marine and freshwater environments.

Industry benefit

Scion business development manager Jeremy Warnes says the PolyNatural® and Scion partnership has been a real success story.

“While not exclusive, our trusted relationship with them dates as far back as 2007 when we started throwing a few ideas around with EPL and exploring ways we can work together to have a positive impact on the environment.

“Our scientists provided biopolymer expertise and research that has helped to kickstart these commercial products. But EPL and now their business unit PolyNatural® must be given enormous credit for developing the technology further and for getting the vine clips market ready.”

Several New Zealand winemakers have successfully trialled the clips, including Cloudy Bay Vineyards in Central Otago and Marlborough. Central Otago Vineyard manager Derek Beirnes describes them as the “perfect product.”

“Each clip does what it needs to do, whilst being environmentally friendly.”

As well as targeting the Adelaide wine growing region, PolyNatural® is planning to export its vine clips to Canada and France, with support from New Zealand Trade & Enterprise.

Innes says winegrowers around the world are hungry for sustainable products. “Everyone knows that they can’t recycle their way out of the environmental plastic problem. We’re very proud of the mahi tahi (collaboration) that has gone into these products, which are providing solutions for New Zealand, in New Zealand, with benefits to the world.

“These products are the future for industry.”