Hemp products for the circular bioeconomy

A hemp revival is gaining momentum, and it is easy to see why. There is no shortage of applications for hemp. From food to bioplastics and even biocomposite construction materials like ‘hempcrete’ (hemp fibres and lime), it is clear this fibrous plant has a lot of potential. Scion is poised to help hemp growers, product designers and innovative brands to cultivate and use this plant in new sustainable products matching the requirements of a circular bioeconomy.

Handy hemp fibres

There is a growing opportunity to use hemp fibres, an untapped waste stream of the hemp growing industry, in various biocomposite or textile applications.

Hemp has long fibres that are suitable for a range of applications including the automotive industries mainly for reinforcement of door panels or as insulation material. It has a high concentration of cellulose, which is great for producing nanocellulose (a thick gel-like material used in nanotechnology and the development of novel and advanced fibres). It is resource-efficient to grow (no fertiliser or irrigation needed), and has high tensile strength, durability, and absorbency. Hemp is also reported to have anti-mildew and antimicrobial properties and due to its fast growth stores a lot of atmospheric carbon dioxide.

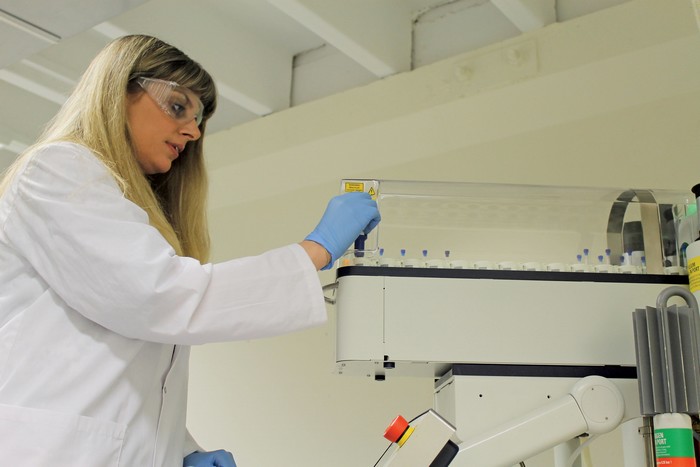

Drs Laura Raymond and Stefan Hill discuss how NMR technology can help hemp growers.

Optimising harvest

Scion scientists Dr Laura Raymond and Dr Stefan Hill has begun developing a fast and inexpensive way to help hemp growers pick the best time to harvest. The test will screen samples of hemp for the chemical signature of selected phytochemicals such as CBD (cannabidiol).

This kind of testing is widespread in the wine and fruit juice industries, where goods are tested to ensure that there are no dangerous contaminants in the products, and to certify that products have not been counterfeited and filled with cheaper substitute materials (e.g. beef mixed with cheaper horse meat sold as pure beef).

The test uses NMR (Nuclear Magnetic Resonance) technology. The NMR will show a spectrum or pattern of chemicals for each sample tested. These results can then be assessed for any patterns from known products (such as horse meat in the example above) to ensure that there are no missing ingredients, or whether any unwanted ingredients are present.

Using hemp as a sample, Laura and Stefan will be looking for the presence of CBD, to ensure that the hemp crop is ready to harvest. This will allow growers to maximise their harvest value.

This test promises to be much cheaper than the existing alternative methods such as GC-MS and LC-MS.

Hemp R&D at Scion

Scion can also test hemp products by other means to assess their environmental credentials and has capability to develop new products. Scion began developing our expertise in natural fibre processing 13 years ago, including post-harvest treatments of hemp fibres and their preparation to suit composite manufacture for the automotive industry within international networks (e.g. Canada, Germany).

Our facilities can test the biodegradability and compostability (DINCERTO accredited), as well as the mechanical properties of hemp. These assurances are vital to organisations looking for green products that are genuinely eco-friendly.

Scion’s current hemp extracts research is being carried out in our in-house testing facilities in collaboration with industry partner Rua Bioscience, and using the cannabinoid testing services of R J Hill Laboratories.

Stefan says, “With research, innovation, and collaboration, hemp will be an important building block in New Zealand’s emerging circular bioeconomy.”