Biobased additive manufacturing

Additive manufacturing (AM), including 3D and 4D printing, encompasses some of the most promising technologies currently available.

News stories regularly appear featuring exciting creations or innovations from houses to human hearts, all made possible with AM technologies. Scion anticipates that AM will continue to be one of the biggest and most influential technologies worldwide. As New Zealand transitions to a circular bioeconomy AM will be a core manufacturing technology going forward.

New Zealand has particularly promising arguments for using AM in our journey to a circular bioeconomy. Our small nation is rich in renewable natural materials that can create the new polymers, composites and other performance filaments that are needed to replace the fossil-based products currently in use.

Scion has 20 years of research and development experience in biomaterials and 10 years in AM; this is forming the basis of a new, innovative manufacturing sector for New Zealand.

Field leading capability

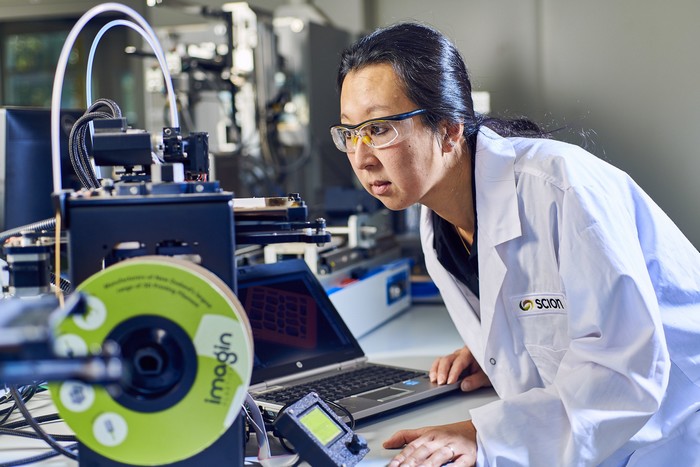

Scion has recently appointed its first Research Leader for Additive Manufacturing - Dr Marie Joo Le Guen. Marie Joo is recognised as one of New Zealand’s leading experts in the 3D printing of biobased materials and she has an impressive industry and national and international academic network. The role will see Marie Joo work with a wider team within Scion and our national and international partners to develop both 3D and 4D printing filaments incorporating renewable resources.

Marie Joo has also been a key contributor in projects with significant additive manufacturing elements including the Science for Technological Innovation National Science Challenge’s (SfTI NSC) 3D/4D printing spearhead project. Scion’s Biopolymers and Chemicals Science Leader Dr Florian Graichen is a co-leader in this project with Dr Kim Pickering from the University of Waikato. Other partners of the multi partner and multidisciplinary collaboration include AgResearch, GNS, Auckland University of Technology, Victoria University of Wellington, Massey University and University of Auckland.

The spearhead project aims to harness New Zealand’s natural resources, such as biopolymers, plants and wood fibres to create new, more environmentally friendly materials and products. Their work includes developing biopolymers for 4D printing, which adds a functionality (i.e. a new dimension) to the 3D printed object such as shape memory. Besides manufacturing the materials, the challenge will design printing processes that can cope with and preserve the natural functionalities of the renewable materials. These new properties could be used to make anything from buildings to furniture.

New research projects

This year, Scion has been successful in securing two new research projects supported by the SfTI NSC seed fund.

Dr Angelique Greene is leading a programme to explore self-cleaning molecular sponges for chemical sequestration. Her work will develop a new method of chemical separation. She plans to create a molecular sponge that uses electrically controlled mechanical motions to selectively trap waste products in one environment and release them cleanly for further processing without saturating the sponge.

Dr Kelly Wade will be leading a project with the AM team to delve into the field of biomedical AM by developing 3D printable polymers containing biologically-active antimicrobial enzymes. He will be working on 3D printable medical devices, such as catheters and orthopedic implants that contain anti-bacterial enzymes, reducing the need for antibiotics while maintaining sterile conditions on the devices. The research will combine recently identified enzymes that remain stable at elevated temperatures with lower temperature 3D printing techniques.

Looking ahead

Looking to the future, our vision for AM includes cross-disciplinary opportunities with other advanced related technologies such as robotics, virtual and augmented reality, and artificial intelligence. For example, the SfTI NSC spearhead teams for 4D printing and robotics are collaborating to identify innovation opportunities on the interface of these two futuristic research domains.

Coupling this highly adaptive technology with the innovative kiwi-mindset, a small but young manufacturing sector, and easy production near supplies of biomass is a recipe for success. This technology will also bring new opportunities to decrease reliance on some imported materials, while increasing exportable products. These factors and more are the reasons to make AM the next big manufacturing direction in New Zealand.