Flexing creativity through innovation

Morphing science, ingenuity and fun were top-of-mind when a Scion team began developing an innovative flexible 4D printing filament that also changes colour with heat.

Sprouting from an idea created for in-house design pitch competition Innovation Jumpstart, Morph, as it’s known at Scion, has now become reality through industry partners, Imagin Plastics.

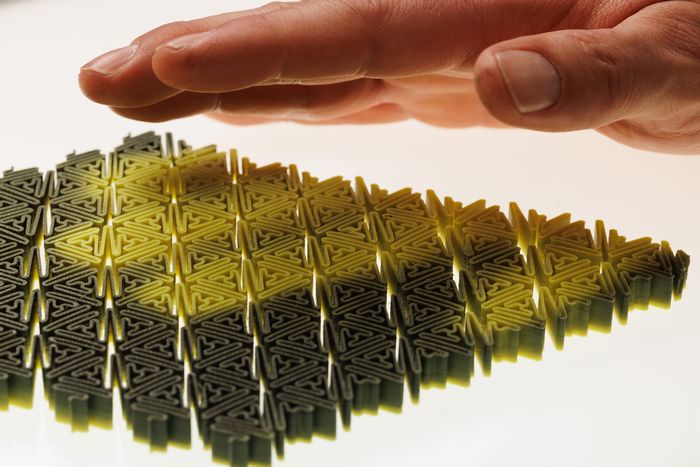

The concept of 4D printing is similar to 3D, where both print three dimensional objects (using length, width and height), but 4D also features an extra dimension that changes over time. So, in Morph’s case, its thermochromic properties means it changes colour with temperature.

Morph development team scientist Angelique Greene says Morph is the only flexible filament of its kind with a stimuliresponsive component.

“There are other fun 4D printing filaments on the market, but they are typically rigid. We wanted to create a unique, flexible filament that had that additional functionality.

“Morph is a flexible filament that is also thermochromic. When it senses a temperature change, like holding it in your hand for example, it changes colour from black to yellow. This is the first product which combines both properties.”

Morph is made from a flexible biodegradable polyester. To date, the Scion team have successfully printed a number of objects, including phone cases, animals such as an octopus and gecko, as well as moveable objects like stretchy bracelets.

Senior materials scientist Robert Abbel says although it sounds self-evident for a 3D or 4D printing filament to actually print objects, it is not guaranteed.

“Flexible materials are more difficult to print than stiff ones, so we were very happy that it performed so well. This opens up a space for creative product prototyping that has been inaccessible with existing products.”

Morph’s commercial potential lies in the education and automation sectors in particular. In the education space, Morph has the ability to teach students about the concept of 3D printing, with an added science component thanks to its flexibility and thermochromism.

Greene says New Zealand is home to a “hobbyist 3D printing army” that will be looking to experiment with a new material as well.

“The true potential of Morph is in the hands of whoever holds it.” Innovation Jumpstart was run by Scion to foster capability and market validation for developing technologies. Despite not winning the in-house competition, Morph made a memorable impact and was subsequently picked up by Imagin Plastics after it was showcased at a Scion industry day.

With the support of the MBIE Pre Seed Accelerator Fund, the Scion team was able to work in partnership with Imagin Plastics to identify and address the challenges to overcome in order to launch the product to the 3D printing market.

Together, the teams at Scion and Imagin Plastics worked on finalising the raw feedstock before it was then turned into a printable filament.

Ben Blakley, sales and technical manager at Imagin Plastics, says what brought the two teams together was the potential around the 4D printing concept.

“We’ve worked with Scion on projects for a number of years in different capacities and the development potential of this project was two-fold for us – building the relationship further and bringing a 4D printing filament into the market.

“Initially we were interested in having a printing material we could see being used in the education sector, like high schools and universities, that had a fourth dimension to it. It opens up opportunities for students to use it for their own research and development.”

Blakley says as well as the education space, Morph has potential in the likes of the automation industry.

“Machine componentry in the packaging and food processing industries, for example, could use the ability to detect temperature change, and even program artificial intelligence to recognise it.”

Greene says now Morph is on the market, the idea is also to have an outreach programme as a way of giving back to the community.

“Our role as a Crown Research Institute is to support industry, but it’s also about supporting the communities in which we operate. It was important to us we found a way to use Morph to do that and the education space is one way in which we can.”

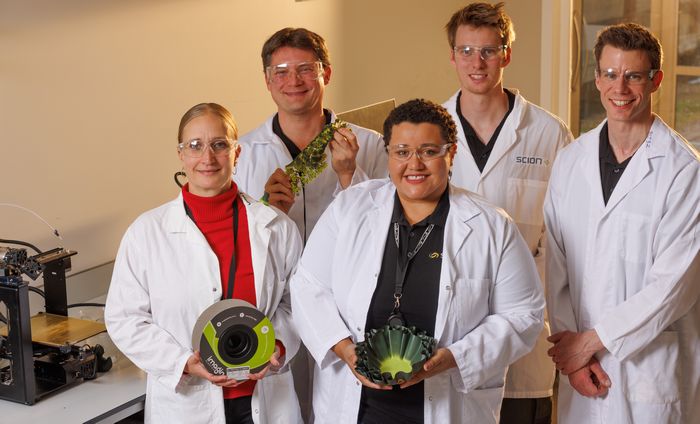

The Scion team that helped bring Morph to life includes Rob Whitton, Beatrix Theobald, Angelique Greene, Robert Abbel and Ben Davy.

Morph is the second printing filament developed commercially in partnership with Imagin Plastics, the first being a wood-based 3D printing filament.

Blakley says: “There’s no rulebook on how we work together; from our perspective, everything’s possible.”

For more information, please contact Angelique Greene.